Alloy Steel Solutions from Solitaire Modern Metals

Introduction to Alloy Steel

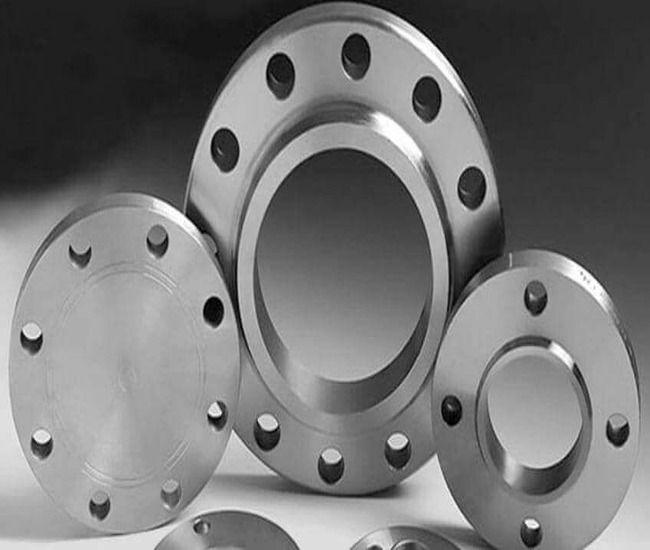

Alloy steel is a high-strength, versatile material known for its exceptional properties, achieved by blending iron with elements like chromium, nickel, and molybdenum. As a leading alloy steel manufacturer, we are dedicated to producing premium-quality alloy steel tailored to meet a wide range of industrial applications. Our expertise and commitment to quality position us as a trusted alloy steel supplier, delivering durable and dependable products across various industries.

Whether you need a reliable alloy steel dealer or an experienced alloy steel stockist, we provide a diverse selection of alloy steel products to support your projects. Discover our range and experience the unmatched performance of alloy steel today.

Some Alloy Steel Grades we offer:

- ASTM A335 P1 Alloy

- ASTM A335 P2 Alloy

- ASTM A335 P5/5B/5C Alloy

- ASTM A335 P9 Alloy

- ASTM A335 P11 Alloy

- ASTM A335 P12 Alloy

- ASTM A335 P22 Alloy

- ASTM A335 P23 Alloy

- ASTM A335 P91 Alloy

- ASTM A335 P92 Alloy

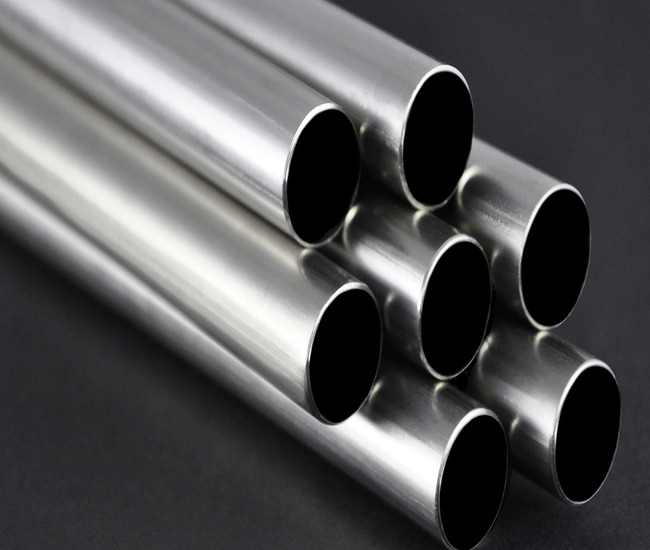

Our Product Range

Schedule and Size Chart

| Schedule | Nominal Diameter (inches) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| Schedule 10 | 0.5″ – 24″ | 1.2 – 4.6 | 1.5 – 38.0 |

| Schedule 40 | 0.5″ – 24″ | 2.8 – 12.7 | 2.8 – 60.0 |

| Schedule 80 | 0.5″ – 24″ | 3.7 – 15.2 | 3.5 – 78.0 |

Mechanical Properties Chart

| Property | Value |

|---|---|

| Tensile Strength | 620 – 1100 MPa |

| Yield Strength | 415 – 860 MPa |

| Elongation (% in 50mm) | 10 – 30% |

| Hardness (HB) | 150 – 300 |

| Modulus of Elasticity | 200 GPa |

Specifications Chart

| Standard | Grade/Type | Description |

|---|---|---|

| ASTM A335 | P1, P5, P9, P11, P91 | Seamless Ferritic Alloy Steel Pipe |

| ASTM A213 | T5, T9, T11, T22 | Seamless Ferritic and Austenitic Pipes |

| EN 10216-2 | 16Mo3, 13CrMo4-5 | Alloy Steel Tubes for High Temperatures |

| JIS G4105 | SCM415, SCM440 | Chromium Molybdenum Alloy Steels |

Chemical Composition Chart

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.10 – 0.50 |

| Chromium (Cr) | 0.30 – 2.50 |

| Molybdenum (Mo) | 0.15 – 1.00 |

| Nickel (Ni) | 0.50 – 3.50 |

| Manganese (Mn) | 0.30 – 1.50 |

| Silicon (Si) | ≤ 0.50 |

Physical Properties Chart

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1,370 – 1,510°C |

| Thermal Conductivity | 25 – 45 W/mK |

| Electrical Resistivity | 0.2 – 0.3 μΩ·m |

| Coefficient of Expansion | 11 – 13 x 10⁻⁶ /K |

Application Chart

| Industry | Applications |

|---|---|

| Energy | Boiler tubes, pressure vessels, and power plants |

| Automotive | Gears, axles, crankshafts, and suspension systems |

| Aerospace | Landing gear, turbine blades, and structural parts |

| Construction | High-strength beams, bridges, and frames |

| Oil and Gas | Drill pipes, casings, and pipeline components |

| Tool and Die | Cutting tools, molds, and dies |