Hastelloy Solutions from Solitaire Modern Metals

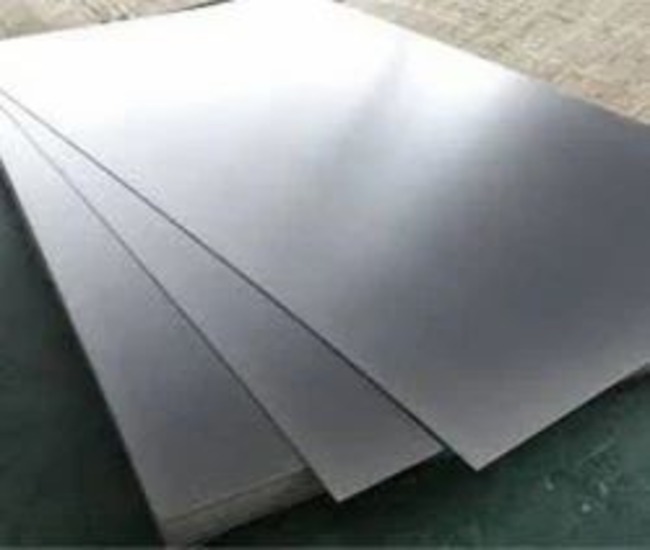

Hastelloy is a high-performance alloy primarily made up of nickel, molybdenum, and chromium, engineered to perform exceptionally in harsh environments. Its unique composition offers outstanding resistance to corrosion and oxidation, making it an ideal material for industries like chemical processing, aerospace, and marine engineering. At ASC LLP, we provide premium Hastelloy products that meet the rigorous requirements of today’s industrial applications.

So, what makes Hastelloy so desirable? Its composition, with nickel for corrosion resistance, molybdenum for enhanced durability, and chromium for oxidation protection, makes it the ideal choice for challenging conditions. Whether you need Hastelloy sheets, plates, pipes, or fittings, ASC LLP delivers high-quality Hastelloy products tailored to your specific needs, ensuring superior performance and long-lasting durability.

Some Hastelloy Grades we offer:

- Hastealloy C276

- Hastealloy C22

- Hastelloy B2

- Hastelloy B3

Our Product Range

Schedule and Size Chart

| Schedule | Nominal Diameter (inches) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| Schedule 10 | 0.5″ – 24″ | 1.2 – 4.6 | 1.8 – 45.0 |

| Schedule 40 | 0.5″ – 24″ | 2.8 – 12.7 | 3.5 – 75.0 |

| Schedule 80 | 0.5″ – 24″ | 3.7 – 15.2 | 4.0 – 85.0 |

Mechanical Properties Chart

| Property | Value |

|---|---|

| Tensile Strength | 550 – 1,200 MPa |

| Yield Strength | 275 – 690 MPa |

| Elongation (% in 50mm) | 30 – 50% |

| Hardness (HB) | 150 – 250 |

| Modulus of Elasticity | 200 GPa |

Specifications Chart

| Standard | Grade/Type | Description |

|---|---|---|

| ASTM B574 | Hastelloy C-276 | Nickel-Molybdenum-Chromium Alloy |

| ASTM B622 | Hastelloy B-2 | Nickel-Molybdenum Alloy |

| ASTM B626 | Hastelloy C-4 | Nickel-Chromium-Molybdenum Alloy |

| ASME SB-574 | Hastelloy C-276 | Corrosion-Resistant Alloy |

Chemical Composition Chart

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50.0 – 72.0 |

| Molybdenum (Mo) | 14.0 – 30.0 |

| Chromium (Cr) | 14.0 – 22.0 |

| Iron (Fe) | 0.5 – 5.0 |

| Tungsten (W) | 3.0 – 4.0 |

| Carbon (C) | ≤ 0.01 |

| Manganese (Mn) | ≤ 1.0 |

Physical Properties Chart

| Property | Value |

|---|---|

| Density | 8.89 – 9.20 g/cm³ |

| Melting Point | 1,300 – 1,400°C |

| Thermal Conductivity | 12 – 16 W/mK |

| Electrical Resistivity | 0.54 – 0.70 μΩ·m |

| Coefficient of Expansion | 13.0 – 14.0 x 10⁻⁶ /K |

Application Chart

| Industry | Applications |

|---|---|

| Chemical Processing | Reactors, heat exchangers, and piping systems |

| Aerospace | Engine components, turbine blades, and exhaust systems |

| Marine | Offshore equipment, desalination systems, and marine pumps |

| Energy | Nuclear reactors, power plants, and petrochemical processing |

| Environmental Systems | Scrubber systems, waste treatment equipment |

| Pharmaceutical | Bioreactors, fermentation vessels, and sterilization equipment |